RESIGUM

ELASTIC WATERPROOF BI-COMPONENT CEMENT COATING

Two component, flexible cement coating, of reduced thickness (approx 2 mm). Recommended for waterproofing below grade walls in masonry and concrete and as a flexible screed for cracked surfaces. Used for treating tanks, swimming pools, vats, concrete piping, for salt- and smog-protective treatment of kerbs, safety barriers, tunnels, overhangs, for waterproofing terraces, technical services areas. It is also widely used as a substitute for bituminous membranes used to waterproof terraces and balconies. It is possible to walk on the product on flat roofs if it is given a protective finish such as RESICOLOR 451 and 475.

RESIGUM is supplied in pre-weighed packages: correctly mixing the two components results in a fluid mortar which can be applied also vertically to carry out 1 – 2 mm thick waterproof and elastic coatings in concrete structures.

Waterproofing capacity of the coating both in terms of water and watery solutions of polluting gasses like nitric oxide, carbon monoxide and sulphur and sulphuric dioxide make RESIGUM the ideal solution for the protection of concrete from freeze/defreeze cycles, penetration of anti-freeze salts and gases typical of aggressive atmospheres. This prolongs the life of concrete structures (industrial buildings, bridges, tunnels and all road network works).

- A RESIGUM coating is highly resistant to aging and preserves in time its elasticity, flexibility and waterproofing features;

- It features good resistance to abrasion which makes it right for pedestrian areas;

- Thanks to its elasticity it can restrain micro-cracks in concrete;

- Good adhesion both on concrete and bricks;

- It can be painted with RESICOLOR 451, 473, 475: these products reduce elasticity of the coating;

- It does not have tar, bitumen and volatile substances.

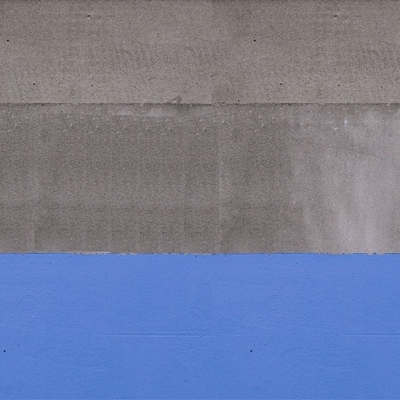

Cement grey colour, other possible pigmentation available only upon request.

| U.M. | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Waterproofing 1,5 UNI EN 12390-8 1.5 atm pressure | No water penetration | |||||||||||||

| Adhesion to concrete | 1,2 | MPa | ||||||||||||

| Permeability to steam UNI 8202-23 | 1000 | μ | ||||||||||||

| Punzonamento statico (*) UNI EN 12730 - metodo B | 20 | kg | ||||||||||||

| Punzonamento dinamico (*) UNI EN 12691 - metodo A | 2000 | mm | ||||||||||||

| Resistenza a trazione UNI EN 12311-2 | 1 | N/mm2 | ||||||||||||

| Allungamento UNI EN 12311-2 | 21 | % | ||||||||||||

| Trazione con rete vetro (150 g/m2) UNI EN 12311-2 | 32 | N/mm2 | ||||||||||||

| Allungamento con rete vetro (150 g/m2) UNI EN 12311-2 | 4 | % | ||||||||||||

| Hardened product volume mass | 2,00 | Kg/dm3 | ||||||||||||

| A + B mixture ratio using mortar | 100 + 33 |

Preparation of the support

Carry out sand-blasting or water cleaning to achieve a clean and healthy bottom, removing any trace of detaching agents, fats and oils, rust and grout.

Even out any imperfections of the foundation (gravel nests, porosities, spacer holes, caissons) and remove possible projecting parts through grinding. Wet the support until it becomes water saturated; puddles and aquaplaning need to be removed before laying the product.

Preparation of the product

Pour component A (powder) into component B (liquid) and blend at slow speed for 3’ – 5’ using drill with helix/spiral until an even and lump-free mixture is achieved.

Application

When correctly mixed, the product is applied using a dented metal spatula, roller or brush, with a maximum thickness of 2 mm per layer. Lay down two coats respecting the time before the second application which may range from 2 to 24 hours depending on the environmental conditions and needs.

With particularly dry or absorbing basements the first coat of RESIGUM may be 5-10% water diluted.

To treat cracked surfaces and waterproof terraces, balconies and pedestrian surfaces we recommend including a fiberglass mesh with 5x5 mm mesh in the liquid sheath. More specifically in case of terraces or flat coverings, it is better to turn up the mesh on the walls for 10 cm high and then carry out the coating.

Notes

Avoid application with high temperatures, with wind or with dry surface: these conditions result in fast evaporation of the mixture water and consequently hydration reaction of the cement cannot be completed. Hardening is only apparent and the coating tends to pulverize.

If you wish to work in such conditions we recommend protecting the coating with wet jute sheets or to spray nebulized water for 1 – 2 days following application.

| Temperature | Time of use | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 °C | 130' | |||||||||||||

| 20 °C | 50' | |||||||||||||

| 30 °C | 20' |

With constanbt curing at + 20°Ce, RESIGUM coating may be walked upon after 18 hours and may be subject to mechanical stress after 4 days. Full hardening occurs after approx. 7 days.

| Walkable | 18 hours | |||||||||||||

| usable | 4 days | |||||||||||||

| Full hardening | 7 days |

| Type of coating | Area of use | Consumption per layer | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| With fibreglass mesh | Terraces, swimming pools, basins, parking areas, bathrooms and pedestrian areas in general. | 2 - 2,5 kg/m2 | ||||||||||||

| With no mesh | Piping, road barriers, curbs, cantilever roofs, plasters with micro-cracks, elevator pits, simple protection against smog, chlorides and sulphates | 1,5 - 2 kg/m2 |

Available in 26.6 kg packages (A + B component).

If stored in its original and sealed package and if kept in dry and sheltered places, the products remains unaltered for at least six months.

- Waterproofing of terraces, swimming pools, bathrooms, roof-gardens, parking places;

- Waterproof coating of basins, tanks, tubes and concrete canals;

- Protection of concrete structures, i.e. curbs, road safety barriers, tunnels and cantilever roofs from salt and smog

- Waterproofing of both outdoor and indoor constructions, i.e. sports complex bleachers, industrial premises, box, utility rooms, elevator pits, flat coverings;

- Direct waterproofing on tiled surfaces with no need to remove them.