RESIFLEX 145

ELASTIC MONO-COMPONENT POLYURETHANE SEALING AGENT

One component, coloured, thixotropic polyurethane sealant - recommended for sealing expansion joints in flooring and between concrete panels, for sealing gutters, flashing and for “active” fissures. Used in waterproofing of hangers of photovoltaic panels. Good chemical resistance, can be painted over and can be used both indoors and outdoors. Available colours – grey.

RESIFLEX 145 is a mono-component polyurethane sealing agent that reacts to humidity in the atmosphere.

Low elastic modulus and excellent adhesive power to concrete make it ideal as elastomer; if applied on

healthy, dry and clean supports, when it reaches full hardening it displays the following features:

- Perfect waterproofing and good resistance to continuous contact with water;

- Good resistance to diluted acids and alkali;

- Good resistance to oils, petrol, gas oil and fuels in general;

- Good resistance to ageing, weathering and UV rays: the product does not become frail and preserves its elasticity for a long time.

| U.M. | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Elastic modulus at 100% (ISO 8339) | 0,25 | N/mm2 | ||||||||||||

| Ultimate elongation (ISO 8339) | 250 | % | ||||||||||||

| Shore A hardness (DIN 53505) | 20 | |||||||||||||

| Resistance to casting at 23 °C (ISO 7390) | ≤ 3 | mm | ||||||||||||

| Vulcanization depth (25 °C - u.r. 50%) | 2mm / 24 hours | |||||||||||||

| Specific weight | 1,30 | Kg/dm3 |

Preparation of the support

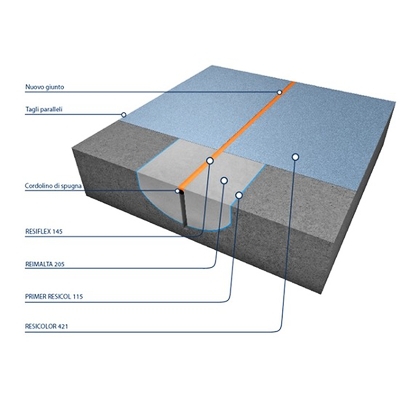

The surface to be treated must be clean, dry, compact and dust and crumbly part-free. Concrete must be fully cured (28 days). In case of surfaces with little cohesion (pulverized), apply RESICOL 106, high

penetration epoxy primer.

The joint must be cleaned with compressed air and a pipe cleaner; do not use water because the product does not adhere to wet surfaces.

Once the crack or cut have been cleaned, insert a stringcourse of expanded polyurethane wider than the width of the joint, 3 – 4mm deep under the surface. Protect edges with sellotape.

Product preparation and application

The product is ready to use: insert the bag in the special gun, open the end before screwing the closing ring and slowly extrude. Smoothen the extruded material by pressing it evenly both against the ends and the middle of the joint.

The product can be applied with temperatures from +5 to +40 °C.

Notes

The bag of RESIFLEX 145 once opened must be used within 30-45 minutes. In case of partial use of the package, close the package with some sellotape; when you want to use it again, cut 2-3 cm of the bag with a cutter removing the already vulcanized part of the product.

When the product is exposed to air, the hardening reaction starts. Its speed is of 2 mm thickness per day at 25°C: when temperature drops, the speed of the reac tion decreases, too.

Dry when touched (25°C - 50% R.H.): 12 hours

The product develops its own functional resistance approx. 48 hours from application.

The product does not change in volume during hardening reaction: to fill in a joint it is necessary to estimate its volume and refer to its specific weight. With a package you may seal 1 m of joint 2 cm deep and 1 cm wide.

Available in grey and black 600 ml packages.

The product remains unaltered for at least six months if sealed in its original containers and kept in a place away from damp with a temperature between 5 and 25 °C.

- Expansion joints in concrete industrial flooring;

- Joints in industrial floorings in the chemical and food sector;

- Joints between prefab walls, connecting joints between passing pipes and bricks;

- Union of brick or concrete buffed panels, etc.

- Sealing of cracks and active fixtures in concrete, stone and bricks;